Brand:Jiantong

Thickness:0.2mm-2.0mm

Width:1m-8m

Color: Black/white

Material:HDPE

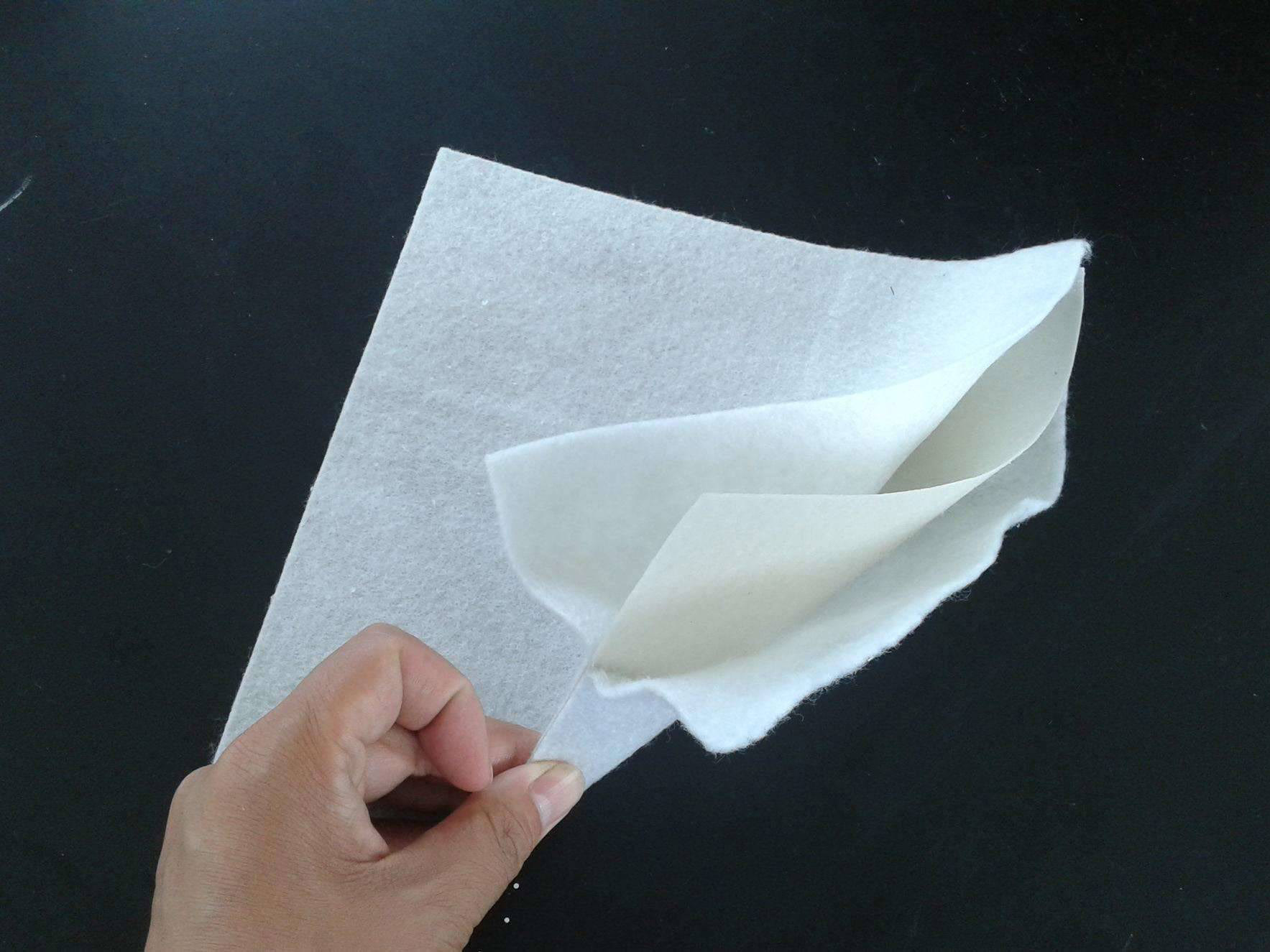

Variety:one side geomembraneand one side geotextile/one side geomembraneand two sides geotextile

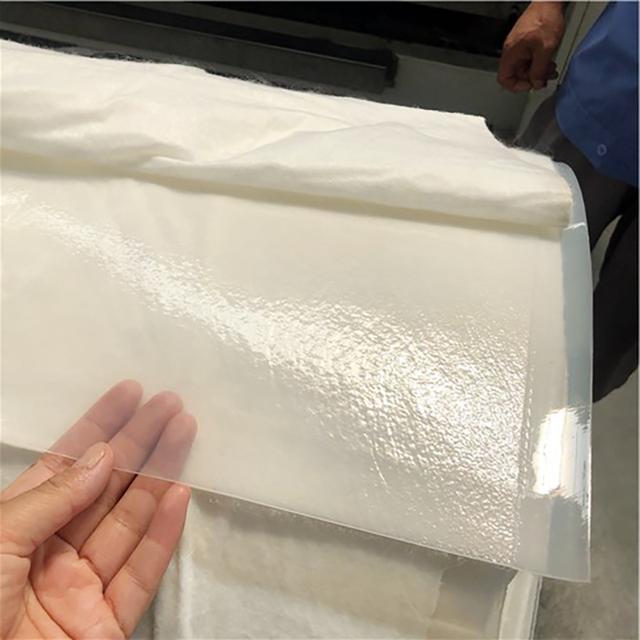

Classification by structure: divided into one cloth and one membrane, two cloths and one membrane and other specifications. For example, the weight range of the base cloth of one cloth and one membrane is 100-1000g/m², and the membrane thickness is 0.1-1.5mm; the weight range of the base cloth of two cloths and one membrane is 80-600g/m², and the membrane thickness is 0.2-1.5mm. In addition, there are special structures such as one cloth and two membranes.

Classification by weight: Common specifications start with SN2/PE, followed by different weight codes (such as 500g, 600g, 700g, etc.). For example, the specifications of 400 grams are 100g/0.2mm/100g, 600 grams are 150g/0.3mm/150g, 700 grams are 150g/0.4mm/150g, 800 grams are 200g/0.4mm/200g, 900 grams are 200g/0.5mm/200g, 1100 grams are 250g/0.6mm/250g, and 1200 grams are 250g/0.7mm/250g.

Excellent anti-seepage performance: The anti-seepage performance mainly depends on the anti-seepage performance of the plastic film. In anti-seepage applications at home and abroad, polyvinyl chloride (PVC), polyethylene (HDPE, LDPE, LLDPE), ethylene/vinyl acetate copolymer (EVA) and other materials are mainly used as anti-seepage substrates.

High physical and mechanical properties: high physical and mechanical properties such as tensile strength, tear resistance, and bursting resistance, with a tensile strength of up to 28MPa and an elongation of up to 700%, which can meet the needs of civil engineering projects such as water conservancy, municipal engineering, construction, transportation, subways, and tunnels.

Good weather resistance: polymer materials are selected and anti-aging agents are added in the production process. It can be used for a long time in unconventional temperature environments, and the service life of the material is up to 50-70 years.

Strong deformation adaptability: It has excellent elasticity and deformation ability, can adapt to the expansion or contraction of the base surface, and ensure the stability of the anti-seepage effect.

Environmental protection and non-toxic: The materials used are all non-toxic and environmentally friendly materials. The anti-seepage principle is based on ordinary physical changes and does not produce any harmful substances.

Water conservancy projects: suitable for anti-seepage, plugging, and reinforcement of embankments of rivers, lakes, reservoirs, anti-seepage of canals, vertical core walls, slope protection, etc.

Environmental protection projects: can be used for anti-seepage treatment of landfills, sewage treatment plants, power plant regulating tanks, industrial and hospital solid waste, etc.

Garden engineering: It is used in the fields of artificial lakes, rivers, reservoirs, golf courses, pond bottoms, slope protection, green lawn waterproofing and moisture-proofing.

Municipal engineering: It is suitable for anti-seepage of subways, underground projects of buildings, planted roofs, roof gardens, and anti-seepage of sewage pipes.

Mining engineering: It can be used for anti-seepage of washing pools, heap leaching pools, ash yards, dissolution pools, sedimentation pools, yards, tailings, etc.

Petrochemical engineering: It is suitable for anti-seepage of chemical plants, refineries, oil storage tanks, linings and secondary linings of chemical reaction pools and sedimentation pools.

Aquaculture: It can be used for lining of intensive and factory breeding pools, fish ponds, shrimp ponds, and slope protection of sea cucumber circles.

Agricultural field: It is widely used in anti-seepage of reservoirs, drinking water pools, reservoirs, and irrigation systems.

Transportation facilities: It can be used for foundation reinforcement of highways and anti-seepage of culverts.