Brand:Jiantong

Thickness:0.2mm-3.0mm

Width:1m-8m

Color: Black

Material:HDPE

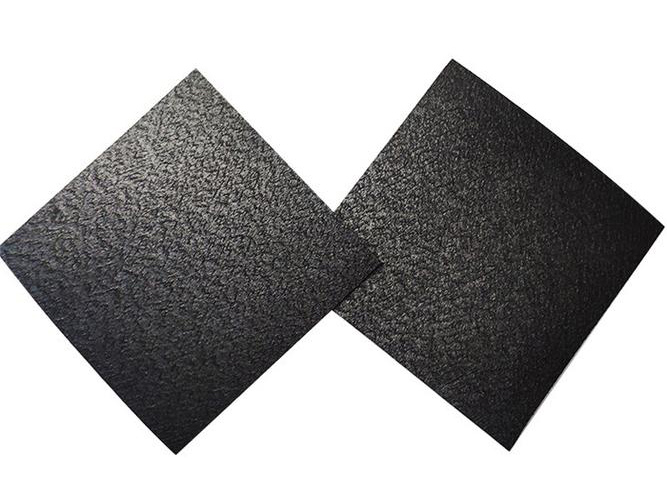

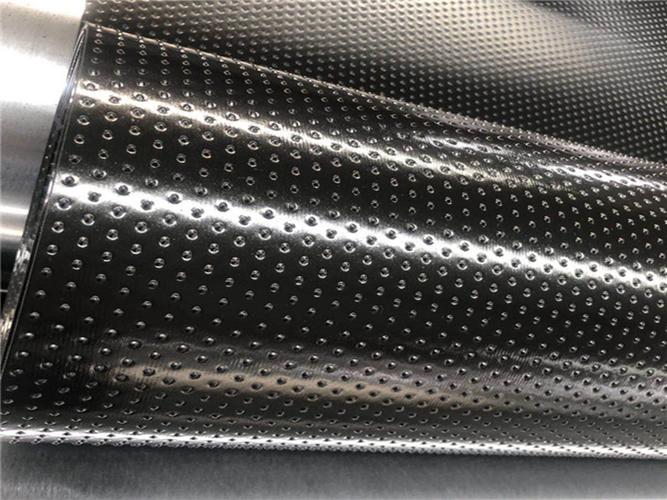

Surface: Textured surface (one side textured/two sides textured), Pin spot surface

Single rough-faced geotextile membrane: One side is rough and the other is smooth. In the construction of slope seepage prevention projects, the rough side is usually facing upwards and in contact with the geotextile fabric, providing a slip-resistant effect.

Double rough-faced geotextile membrane: Both sides have rough surfaces. It has a wide range of applications. In the construction of slope seepage prevention projects, it can be in contact with the geotextile fabric, providing a slip-resistant effect.

Column-point geotextile membrane: One or both sides have uniform protrusions. The rough points are evenly distributed and aesthetically pleasing. It can be applied in slope seepage prevention projects, achieving the effects of seepage prevention, slip resistance, and anti-pollution. Characteristics

High seepage coefficient: It has a permeability coefficient that is incomparable to ordinary waterproof materials, generally K < 1.0×10⁻¹³g·cm/(cm²·s·Pa).

Good chemical stability: It has excellent chemical stability, widely used in sewage treatment, chemical reaction tanks, landfill sites, etc., resistant to high temperatures, asphalt, acids, alkalis, and more than 80 kinds of strong acid and strong alkali chemical media corrosion.

Excellent aging resistance: It has excellent anti-aging, anti-ultraviolet, and anti-decomposition capabilities, can be used exposed, and the material service life can reach 50 - 70 years.

Resistant to plant roots: It has excellent anti-penetration performance, can resist most plant roots.